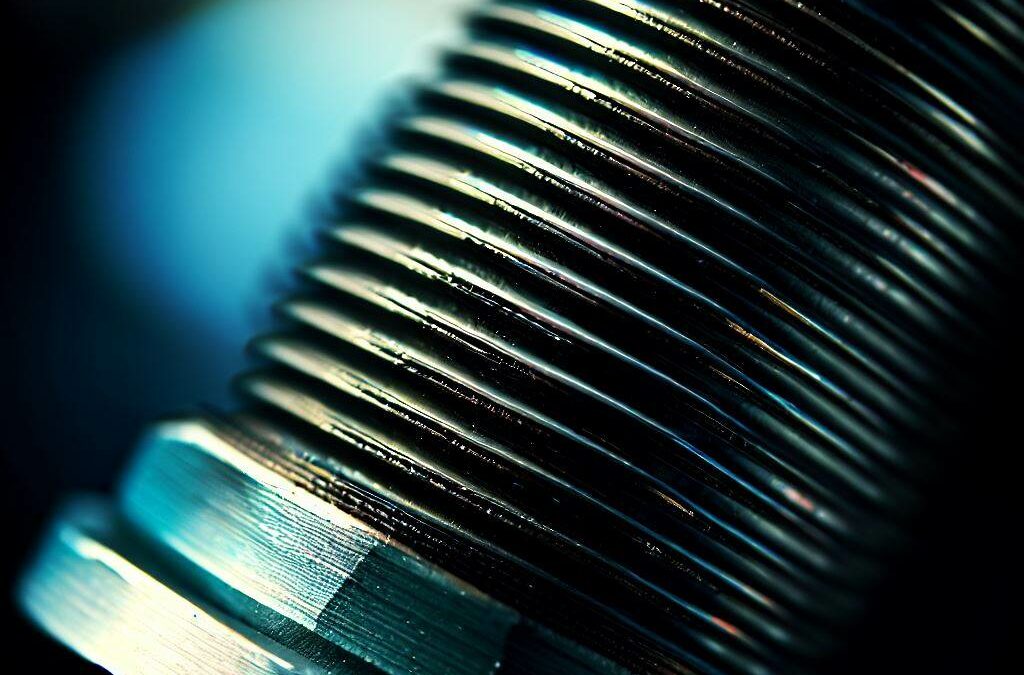

Identifying hydraulic threads is crucial in the maintenance and repair of hydraulic equipment. Inaccurate identification can lead to costly mistakes, such as improper assembly, leaks, and equipment failure. In this blog, we will provide a guide on how to identify hydraulic threads, including the most common thread types, thread measurement techniques, and identification tips.

Types of Hydraulic Threads

There are several types of hydraulic threads commonly used in hydraulic equipment, including:

- NPT (National Pipe Thread): NPT threads are the most common type of hydraulic thread in North America. They are tapered and come in male and female versions.

- BSPP (British Standard Pipe Parallel): BSPP threads are commonly used in Europe and Asia. They are parallel and come in male and female versions.

- BSPT (British Standard Pipe Tapered): BSPT threads are also commonly used in Europe and Asia. They are tapered and come in male and female versions.

- JIC (Joint Industry Council): JIC threads are used in high-pressure hydraulic systems. They are straight and come in male and female versions.

Measuring Hydraulic Threads

Measuring hydraulic threads requires accurate measurement tools and techniques. The most common methods of measuring hydraulic threads include:

- Thread pitch gauge: A thread pitch gauge is used to measure the pitch of threads. It is placed on the thread to determine the distance between each thread.

- Caliper: A caliper can be used to measure the outer diameter (OD) and inner diameter (ID) of the thread.

- Thread ring gauge and plug gauge: These gauges are used to determine if the threads are within specification. The thread is screwed onto the gauge, and if it fits correctly, the threads are within tolerance.

Identification Tips

Identifying hydraulic threads can be challenging, but there are some tips that can help:

- Look for markings: Threads may have markings that indicate the thread type, size, and manufacturer.

- Compare threads: Comparing the thread to a known thread type can help identify the thread.

- Consult a chart: There are many charts available that can help identify hydraulic threads based on their size and shape.

Identifying hydraulic threads is essential for the proper maintenance and repair of hydraulic equipment. Knowing the most common thread types, thread measurement techniques, and identification tips can help ensure accurate identification and prevent costly mistakes. If you are unsure about the thread type, size, or specification, contact the team at Texas Hydrostatics for assistance.