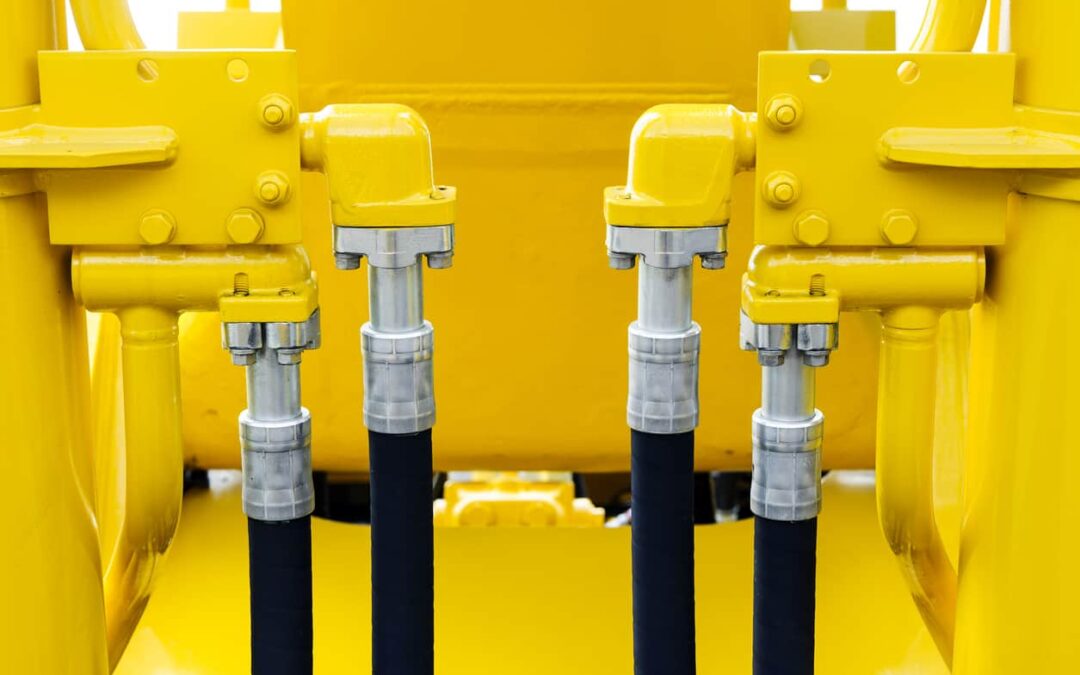

The hose-coupling interface is a crucial component in hydraulic systems. It connects the hydraulic hose to the equipment and ensures the transfer of hydraulic fluid. However, several issues can arise at the hose-coupling interface, resulting in equipment failure, leaks, and safety hazards. Let’s look at the causes and solutions of hose-coupling interface issues.

Causes of Hose-Coupling Interface Issues

There are several reasons why hose-coupling interface issues can occur, including:

- Improper Assembly: Incorrect assembly of the coupling and hose can cause leaks and failures. This can be caused by incorrect tightening torque or incorrect placement of the coupling.

- Wear and Tear: Over time, the coupling and hose can wear out due to constant use, abrasion, and exposure to harsh environments. This can result in a loss of seal and fluid leakage.

- Mismatched Components: Using mismatched components, such as a hose with a coupling of the wrong size or type, can result in leaks and equipment failure.

- Improper Storage: Storing hoses and couplings improperly, such as in areas exposed to high temperatures, sunlight, or chemicals, can cause degradation and failure of the components.

Solutions to Hose-Coupling Interface Issues

There are several solutions to prevent or resolve hose-coupling interface issues, including:

- Proper Assembly: Ensure that the coupling and hose are correctly assembled by following the manufacturer’s guidelines and using the correct tightening torque.

- Regular Maintenance: Regularly inspect the coupling and hose for wear and tear, and replace them as needed. Regular maintenance can prevent equipment failure and safety hazards.

- Matched Components: Use matching components, such as a hose and coupling of the same size and type, to ensure a secure and leak-free connection.

- Proper Storage: Store hoses and couplings in a clean, dry, and cool environment to prevent degradation and damage.

Consulting Texas Hydrostatics can help you prevent hose-coupling interface issues that lead to equipment failure, leaks, and safety hazards. Understanding the causes of these issues, such as improper assembly, wear and tear, mismatched components, and improper storage, can help prevent them from occurring. Regular maintenance and inspection of hoses and couplings can ensure their proper functioning and prevent costly equipment failure. If you are experiencing hose-coupling interface issues, call our professionals at Texas Hydrostatics right away.