Texas, the heart of the industry, thrives on the power and precision of hydraulic systems. These systems are the workhorses behind many operations. They are used in construction, manufacturing, and oil and gas production. A critical, yet often overlooked component of any hydraulic system is the reservoir. A good reservoir does more than store fluid. It also plays a vital role in optimizing system performance, efficiency, and, ultimately, lifespan.

The Reservoir: More Than Just Storage

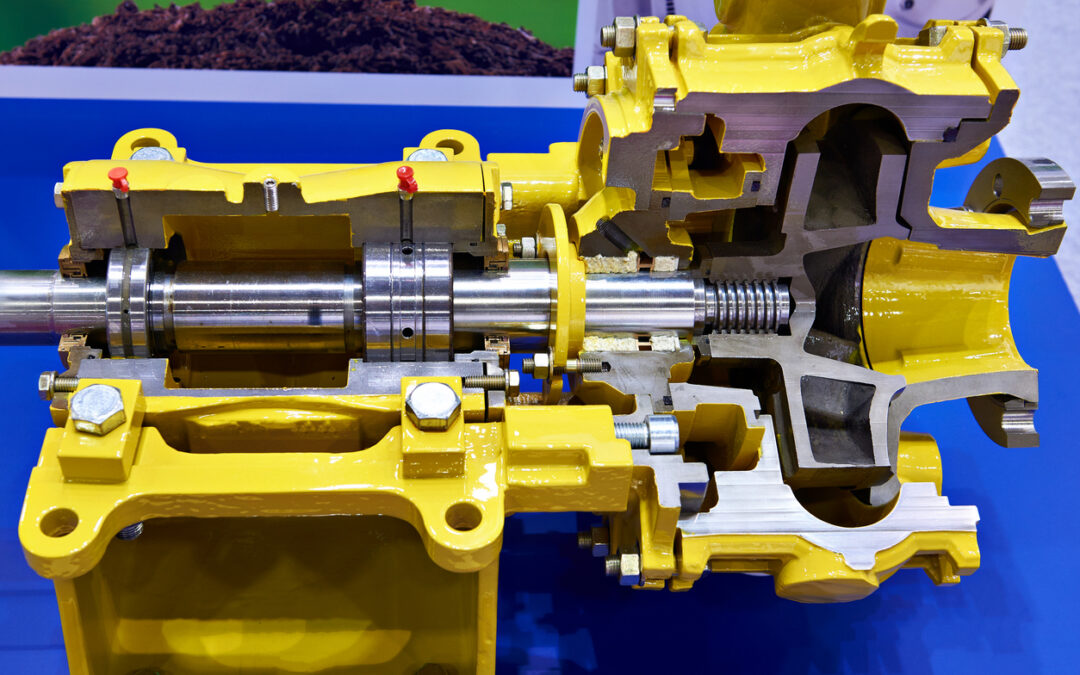

A hydraulic reservoir acts as the lifeblood of your system, storing the hydraulic fluid that powers its operation. However, its function extends far beyond mere storage. A well-designed reservoir performs several critical tasks:

- Heat Dissipation: During operation, hydraulic systems generate heat. An appropriately sized reservoir acts like a heat exchanger. It helps transfer heat from the fluid to the surrounding environment. This prevents overheating, a critical factor in ensuring system reliability. Experienced hydraulic system designers carefully consider factors. When selecting the appropriate reservoir size and material, they look at workload demands and ambient temperatures.

- Contamination Control: Contamination is the enemy of any hydraulic system. Contaminants like dirt, metal shavings, or even water can cause component wear. They also reduce efficiency and ultimately lead to system failure. Reservoirs equipped with features like baffle plates and breathers act as the first line of defense. Baffle plates help separate contaminants by directing fluid flow within the reservoir. Breathers allow air to escape without introducing new contaminants into the system. Some reservoir designs incorporate additional filtration elements. These filters protect the system from internal threats.

- Air Entrapment Prevention: Air bubbles can disrupt system operation and cause cavitation damage within components. Cavitation happens when air bubbles collapse under pressure. This creates tiny shockwaves that erode internal surfaces. A well-designed reservoir allows air to rise and escape through strategically placed breathers. This ensures smooth operation and protects your system from internal damage.

- Maintaining Optimal Fluid Level: Reservoirs function as a buffer, maintaining a consistent fluid level for optimal pump performance. A consistent fluid level prevents cavitation, which can occur when the pump inlet isn’t submerged, and protects the pump from damage. Level gauges and alarms integrated into the reservoir design help monitor fluid health and prevent potential issues.

Optimizing Design for the Texas Environment

Texas has unique environmental challenges. They require special considerations when designing a hydraulic reservoir.

Temperature Fluctuations

Texas experiences wide temperature swings throughout the year. Selecting the suitable reservoir material is crucial. It ensures the reservoir maintains its structural integrity and doesn’t warp or crack due to temperature fluctuations. Materials like steel or stabilized polyethylene can withstand these variations, ensuring consistent performance.

Dust and Debris

The Texas environment can introduce airborne dust and debris into your system. Incorporating additional filtration elements within the reservoir design can address these potential threats. This proactive approach prevents dust and debris from entering the working fluid and causing wear and tear on components.

Maximize Hydraulic System Performance in Texas

Is your Texas-based hydraulic system experiencing decreased performance, overheating, or frequent component failures? Texas Hydrostatics, Houston’s leading hydraulic repair and remanufacturing specialists, has the expertise to get you back on track.

Led by Steve Seckel, our head hydrostatic engineer with a proven track record and meticulous attention to detail, our team possesses extensive experience diagnosing and resolving a wide range of hydraulic system issues. We don’t just fix problems; we find the root cause and recommend comprehensive solutions to ensure long-term system health.

Contact Texas Hydrostatics today for a free consultation! Let our team assess your specific needs. We will develop a customized plan to optimize your hydraulic system’s performance and lifespan.