Why Replace When You Can Remanufacture? Discover the Smart Choice for Hydraulic Systems

Hydraulic systems are the lifeblood of many industrial sectors, from construction and agriculture to oil and gas. The performance of these systems depends heavily on the condition of their components, such as pumps, motors, and valves. When these components fail, companies often face a dilemma: replace the parts with new ones or opt for remanufacturing. Remanufacturing, which involves restoring used components to like-new condition, offers a cost-effective, high-performance alternative. In this article, we’ll explore the benefits of remanufacturing hydraulic components and why it’s a smart choice for businesses seeking sustainable and economical solutions.

Cost Savings: Spend Less, Gain More

One of the most compelling benefits of remanufacturing hydraulic components is cost savings. New hydraulic parts can be expensive, particularly for high-quality, branded components. Remanufacturing, however, can reduce costs by up to 50% compared to buying new parts. This is because the core of the component is reused, with only worn-out or damaged parts being replaced. For businesses operating on tight budgets or managing large fleets of machinery, these savings can significantly impact the bottom line.

- Lower Acquisition Costs: Remanufactured components often cost a fraction of their new counterparts.

- Minimized Downtime: Remanufactured parts can be delivered faster, reducing equipment downtime and associated costs.

- Extended Equipment Life: By remanufacturing, you can extend the life of your equipment, delaying the need for costly new purchases.

Improved Performance: Like New, Sometimes Better

Contrary to common belief, remanufactured components can match or even exceed the performance of new ones. At Texas Hydrostatics, we specialize in restoring hydraulic components to OEM (Original Equipment Manufacturer) specifications. This means that each remanufactured part is meticulously inspected, cleaned, and tested to ensure it performs like new.

- Quality Assurance: Every remanufactured component is rigorously tested to meet or exceed original performance standards.

- Upgraded Features: Sometimes, remanufactured parts include upgrades or enhancements that weren’t available in the original versions, providing better durability and performance.

Environmental Impact: A Sustainable Choice

The environmental benefits of remanufacturing are substantial. By reusing core components and reducing the need for new raw materials, remanufacturing significantly lowers the carbon footprint of hydraulic systems.

- Reduced Waste: Remanufacturing prevents used components from ending up in landfills, contributing to a circular economy.

- Energy Savings: The energy required to remanufacture a part is much lower than producing a new one, reducing greenhouse gas emissions.

Why Choose Texas Hydrostatics for Remanufacturing?

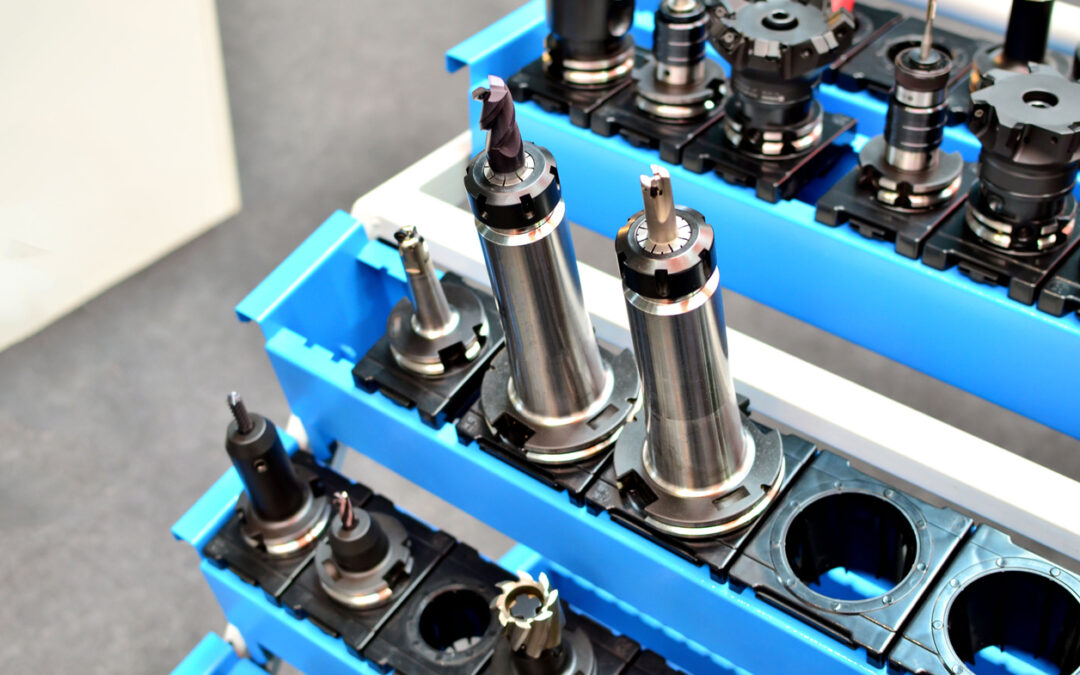

At Texas Hydrostatics, we are committed to delivering top-tier remanufacturing services for hydraulic pumps, motors, and valves. Our team of highly skilled technicians utilizes state-of-the-art equipment to restore components from leading brands such as Danfoss, Rexroth, and Eaton. Whether you’re in construction, agriculture, or the waste management sector, we understand the critical role hydraulic systems play in your operations. By choosing us, you’re not just saving money—you’re investing in quality and reliability.

Ready to Save on Hydraulic Component Costs? Contact Texas Hydrostatics Today!

Don’t let hydraulic component failures slow down your business. Contact Texas Hydrostatics to learn how our remanufacturing services can keep your equipment running at peak performance while saving you money. Our expert team is here to help you find the most cost-effective and sustainable solutions for your hydraulic needs. Contact us today to discuss your specific requirements and discover the benefits of remanufacturing with Texas Hydrostatics.

By choosing remanufacturing, you’re making a smart investment in your business’s future. Let us show you how.